Ensure the

success of your hose assembly operation with Eaton’s crimp machines and

tooling. With the new Eaton-branded crimp machine portfolio, both Aeroquip™ and

Weatherhead™ customers have access to the same crimp machines and tooling! This

simplified and improved offering with lower cost options is comprised of

positive stop and variable crimpers in portable, general service, and

industrial production options to meet all your application needs.

Put your

mind at ease assembling, selling, or using Eaton warrantied hose assemblies

made with Eaton’s superior hose products, hose ends, assembly machines, and

tooling. Eaton’s resource website, eatonpowersource.com, has up to date crimp

spec information to ensure a properly crimped and safe hose assembly. Access

the PowerSource Crimp Specs tool at www.eatonpowersource.com/crimp-specs/.

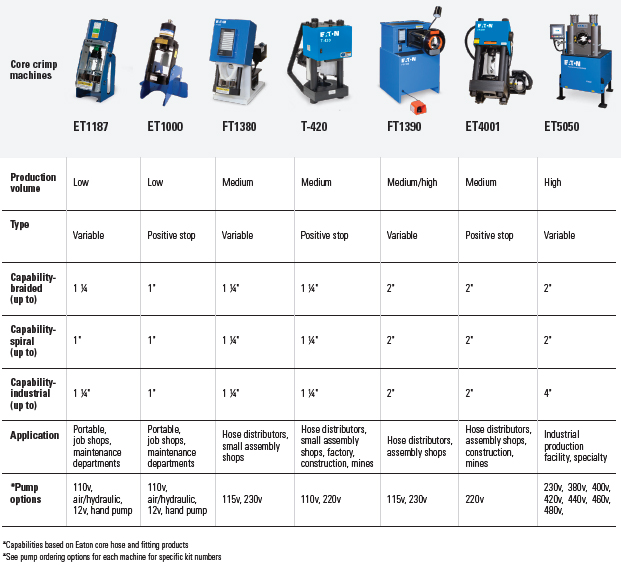

The ET1187

machine is our most economical variable crimp machine to date. It boasts a

broad crimp capability and “ease-of-use” dial. This machine is designed to

easily adjust to Eaton’s core products. It’s as simple as turning the collar to

the correct color to match the lay line on the hose, adjust the ring so that

the correct size dot aligns with the correct size line on the collar and the

machine is set for the proper crimp. Load the correct crimp die based on the

crimp die chart attached to the machine, and the machine is ready to crimp. A

version of the machine for Eaton Winner hose is also available.

The

portable ET1000 crimp machine has four pump options and comes equipped with a

stand pre-drilled for mounting to a workbench or table-top. This simple

positive stop machine offers consistent crimping time after time with no

operator adjustments required and is easily transported between job sites.

The FT1380

crimp machine crimps all your hose needs up to and including -20 4-wire spiral

hose. The FT1380 is electronically controlled to give fast, accurate crimps the

first time and every time you need a hose assembly. The electronic keypad is

easy to adjust, with up to 10 programmable crimp settings. For hose styles and

sizes used less frequently, simply enter the 3-digit target setting.

The T-420

is a versatile positive-stop machine ideal for your shop, factory, construction,

and mine locations. Large capacity combined with lever-activated crimping gives

you wide coverage and a quick and simple way to make factory-quality hose

assemblies.

The FT1390

crimp machine is a stand-alone machine and will crimp up to 2″ braided, 2”

4-wire spiral, and 2” 6-wire spiral hydraulic hose assemblies. It boasts a

programmable electronic keypad with 10 presets. This keypad simplifies the hose

crimping operation by allowing the machine operator to enter a predetermined

setting for a specific hose type and size. The ten most often used crimp

settings can be stored for one-touch retrieval. The machine will automatically

crimp to the exact crimp diameter required for that hose type and size. The

electronic crimp machine settings eliminate the need for spacers or shims in

the crimping operation.

The ET4001

is ideal for factory, high-performance machine operations, construction, and

mine locations. This machine offers the capabilities of crimping all the

crimp-style hose ends through -32. With this coverage, this heavy-duty

positive-stop crimper can handle all your crimping needs.

The ET5050

is designed for high industrial production and comes pre-programmed with all of

Eaton’s hose and hose fitting crimp specifications, crimp profile details, and

machine settings to crimp to Eaton’s specifications. It crimps up to 2” spiral,

2” braided, and 4” industrial in Eaton core hose products as well as a wide

variety of specialty hose. The ET5050 crimp machine took on a new look in

January. The updates were made in an effort to reduce lead times and pricing as

the machine now ships directly from Uniflex in the Chicago suburbs.

Eaton

crimpers are favored in the field. See what others are saying.

“The Eaton

crimp machine offers the best in positive stop or variable crimp technologies.

With Eaton, I can offer my customer a crimper that matches their needs.”

“I

appreciate the simplicity of Eaton’s assembly system.”

“’I have been

selling Eaton Aeroquip & Winner fittings since 1976 and as of 2019, Eaton

now offers the greatest array of crimp machines in all the years I have dealt

with them.The size range covered

involving both stationary and mobile machines is complete and the choice of

either variable crimp or positive stop crimping systems with its full array of

options lends a solution to any/all of our crimping needs.We sell in three channels including OEM, MRO

and Retail.In each case, we are able to

not just meet the needs of our customer base but moreover we exceed it.The operation and set up of the machines is

simple to understand.Our incidence of

placing hydraulic crimp machines has never been higher and invariably, the

features and benefits of the Eaton machines eclipse the competitor’s machines.We are realizing great growth with the Eaton

line and the new machine offering is pivotal to our growth.”

Eaton

crimpers are durable and suitable for any environment, including hose centers,

mines, and construction sites.Their ability to

be mounted to work vehicles make their versatility even greater as on-site

assemblies can be brought right to the application area. The simplicity of

their design ensures ease of use from the novice to the most experienced

assembler.

Eaton makes crimping simple. To find the

proper crimp spec anytime and anywhere, the mobile crimp spec tool is

available on PowerSource! Visit www.eaton.com/crimp on your mobile

device and add to your favorites for quick access. To find your spec, simply

select your machine, hose

series, hose size, and fitting style, and you’re

ready to crimp!